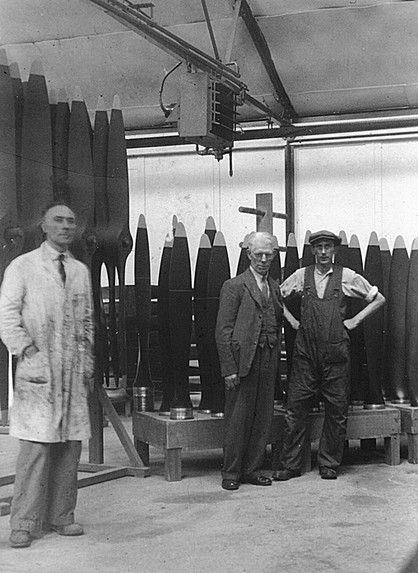

Whilst Thomas Cholmondeley Tapper and Dennis Fox had been getting the

airfield up and running they were approached by a friend, the Duke of

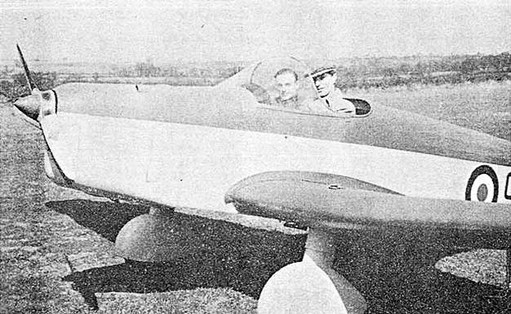

Richmond & Gordon, (in partnership with Edmund Hordern who had been

the Heston Aircraft Co.’s test pilot), with a proposal to build a factory

on the airfield to make aircraft propellers using a new

process known as ‘Hydulignum’. This was a high-density wood laminate,

(Lignum Vitae is so dense it doesn’t float, from the West Indies it is

also known for its medicinal properties) and was soon to be used on

various aircraft including I believe aircraft of Wellington

size.

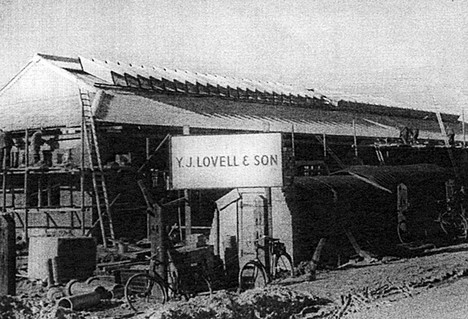

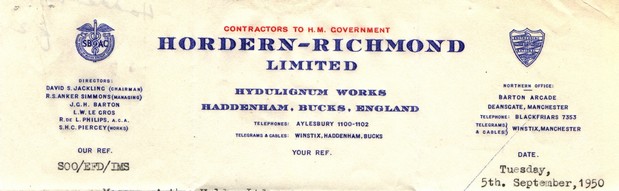

Early in 1939 the Hordern-Richmond Co. leased 4 acres of CTF

land on the south eastern edge of the airfield next to Windmill Road and

soon built their factory there.

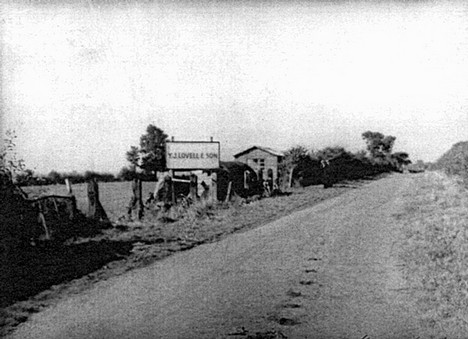

Windmill Road just before work started on the propeller factory.